Reliability and performance

-

Medians

-

Under a girder bridge

-

Photos show you the progress 15after the operation

Quality

- Made of high-quality decomposed granite soil

- A stable pre-mixed product with less non-uniformity

Environment and safety

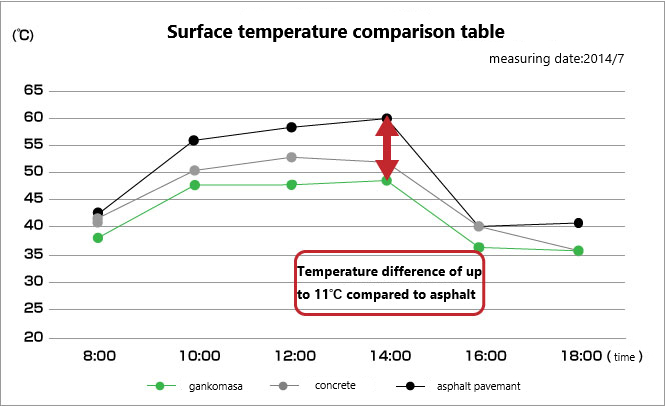

- GANKOMASA mitigates the reflected heat in summer.

(Heat island phenomenon suppression effect)

Main uses

-

Medians

-

Planting strips

-

Delineators on highways

-

Ditches next to railway tracks

-

Planting strips on pavement

-

Factory greening

Operation results

-

Zentsuji City, Kagawa Prefecture

(medians) -

Awaji City, Hyogo Prefecture

(medians) -

Okazaki City, Aichi Prefecture

(The shoulder of National Route 1)

Operation Design Standard

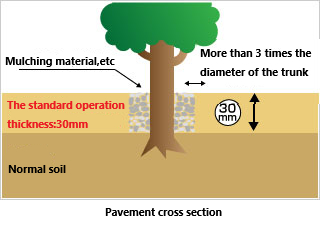

For the foundation of GANKOMASA, compact the undisturbed soil.

If the condition of the foundation is not good, add crusher-run stones and form a proper foundation (roadbed).

For the protection of trees, installation should be done with enough space for tree trunks (3 times the diameter of the trunks as a standard), and mulching material should be added.

Construction Procedure

-

Foundation Correction

Do weeding and smooth uneven terrain first, and then do the rolling compaction on the roadbed.

* Please remove weeds from the roots

* Use compacting equipment, hand-guided rollers (walk behind type rollers), etc. for the rolling compaction. -

Leveling and Surface Correction

Correct surface unevenness with rakes, and make the drainage slope.

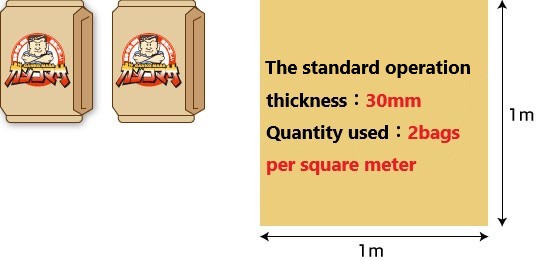

Quantity used: 2 bags per square meter (Thickness: 30mm) -

Brushing

Brushing makes a uniform finish, and removes the deviations caused by particles on the surface. Brush smoothly and lightly on the surface.

-

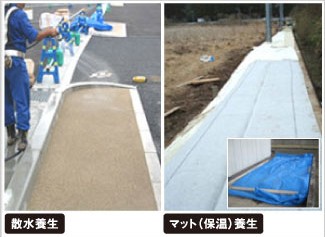

Water sprinkling

Sprinkle water over the whole surface uniformly. Sprinkle water until it comes up to the surface, and do it 3 times at 5- or 10-minute intervals. Needed water: 8-9 liters per square meter (thickness: 30mm)

-

Excavating and confirming the permeation

Excavate the surface, and check the permeation of water by sight.

*Confirm that the water permeates more than two-thirds of its thickness. If it is not enough, sprinkle water again. -

Curing

After the operation, sprinkle water for curing. Do the same operation the next day if doing in summer. Do the curing with a mat in winter.

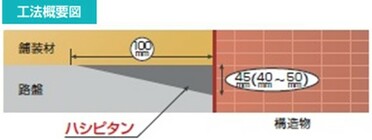

Combination construction method

Merits

- Shutting out Weeds which come out from cracks

- Easy to operate, just laying and leveling

- As it is used with the original foundation,it won’t change the texture of the pavement.

- No chemicals used

- Use of recycled aggregate

Precautions

- Use compacting equipment, hand-guided rollers (walk behind type rollers), etc. for the rolling compaction of the foundation (roadbed).

- Use wooden or plastic trowels, and NOT metal trowels.

- Stiffening defects might occur due to deficiency and excess of watering.

- Don’t proceed with installation when it rains or snows.

- To avoid freezing, don’t proceed with installation when the temperature is below 5 degrees Celsius.

- Do not use it indoors.

Specification

The comparison table for the temperature of the surface

Precautions

- Efflorescence (crystalline salt deposits), cracks, or moss might occurdue to the conditions at the site.

- Wear masks, gloves, and dust-proof glasses when using.

- Allow enough space for tree roots so as to not inhibit the growth of trees.

- Store in a place with low humidity, and finish using all material after opening the bag.

Options

-

Sheet pallet

a product with a registered design

Reduces the unloading work, and eliminates the manual unloading process when it’s brought to the site. Cab be fully opened easily with Velcro!

Suppression for moss and mold

It suppresses stains and dirt on the pavement surface.

Package

- 25kg bag / 500kg flexible container / 1t flexible container

Progressive condition of inhibitory effect on moss and mold

-

A newly finished operation from 2011

Surface of slope with SUPER GANKOMASA

-

2014, 3 years after the operation

The back side of the slope uses the standard type, and front side has been done with the moss and mold suppression type.

You can see that the standard type has some stains, but the suppression type has retained the same color as when the operation was done.

-

2017, 6 years after the operation

The back side of the slope uses the standard type, and front side has been done with the moss and mold suppression type.

The suppression type has kept its effect even 6 years after the operation.

Condition of moss and mold growth

-

Black mold has appeared (left)

With the moss and mold suppression type (right) -

Moss appeared on the black mold.

-

Moss spread out.

Under conditions with shade or humidity, moss will grow more easily and the suppression may differ from the usual conditions.